Home Page » دسته بندی نشده » What are the common causes of fuse failure?

What are the common causes of fuse failure؟

However, fuse failure can lead to sudden equipment shutdowns, increased safety risks, and significant repair costs. Timely identification of the cause of fuse failure helps prevent recurrence and extends the lifespan of electrical equipment.

In this article, we examine the common causes of fuse failure, warning signs, prevention methods, and troubleshooting techniques to help engineers, electricians, and maintenance teams maintain safe, stable, and reliable electrical systems.

What Is Fuse Failure? | Definition and Types of Fuse Failure

Fuse failure refers to a condition in which a fuse cannot properly perform its primary function—protecting the electrical circuit. This may result in either failure to disconnect the circuit during hazardous conditions or unwanted tripping during normal operation, both of which can have serious consequences.

Understanding the different types of fuse failure is essential for proper protective system design and improving electrical circuit safety.

Common Types of Fuse Failure

1. Open Failure

In this case, the fuse blows due to excessive current and opens the circuit—this is the expected protective behavior.

However, open failure may also occur due to fuse aging, degradation, or mechanical fatigue, even without an actual overcurrent condition.

2. Short-Circuit Failure

This type of failure is rare but extremely dangerous. In this situation, the fuse element welds together after melting and fails to interrupt the circuit during a fault. Such conditions can cause severe equipment damage and significantly increase the risk of fire.

3. Nuisance Blowing

Nuisance blowing occurs when the fuse operates under normal and permissible current levels. This issue is usually caused by:

Incorrect fuse rating selection

Failure to consider ambient temperature

Fuse aging and wear

A proper understanding of fuse failure types helps you select the correct fuse, prevent unnecessary interruptions, and enhance circuit safety—forming a critical foundation for effective protection design in residential, commercial, and industrial applications.

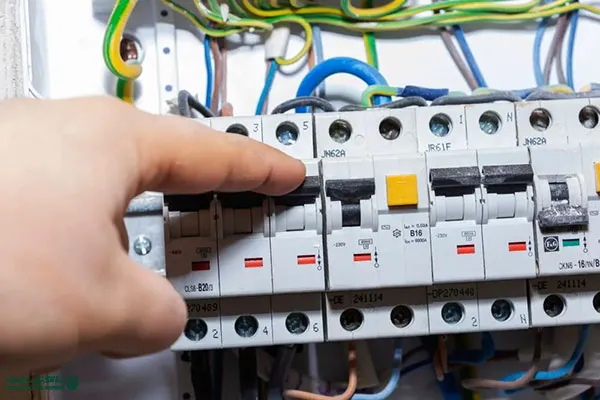

1. Faulty Building Wiring and Defective Outlets

One of the most common reasons for fuse tripping and power outages is faulty building wiring. Improper cable installation, insulation deterioration, use of low-quality wires, or short circuits can cause excessive current flow and increased circuit temperature. In such cases, the fuse operates correctly by disconnecting the power to protect equipment and prevent potential hazards.

Defective outlets or aging wiring can also disrupt proper current flow, leading to unstable electrical conditions and repeated fuse tripping.

2. Electrical Overload and Short Circuit

Electrical overload and short circuits are among the most frequent causes of fuse failure. When the current exceeds the fuse’s rated value, the internal element heats up, melts, and opens the circuit to prevent equipment damage and fire hazards—this is the fuse’s normal protective function.

However, under certain conditions, fuse operation may become unexpected or repetitive due to:

High inrush currents during equipment startup

Sudden or temporary short circuits

Incorrect fuse rating or insufficient I²t value

Role of I²t in Fuse Failure

The I²t parameter represents the amount of energy that passes through the fuse before it interrupts the circuit. If this value is not compatible with actual circuit conditions and transient currents, premature fuse blowing may occur even during normal operation.

3. Mechanical Vibration and Shock

In industrial and automotive applications, mechanical vibration and shock are significant contributors to fuse failure. Continuous vibration can cause micro-cracks in the fuse element or loosen terminal connections, resulting in intermittent contact, unexpected circuit interruption, or open failure—even in the absence of an electrical fault.

4. Extreme Temperatures and Ignoring Current Derating

Operating a fuse at temperatures above its rated ambient temperature reduces its allowable current capacity and shortens its service life. High temperatures accelerate material oxidation and weaken the fuse element, while extremely low temperatures can make materials brittle and prone to fracture.

Ignoring temperature derating curves during fuse selection often leads to frequent nuisance tripping and increased operational risks.

5. Improper Installation and Poor Electrical Contact

Incorrect installation practices such as:

Loose terminals

Incorrect tightening torque

Use of incompatible fuse holders

increase contact resistance and localized heating. This accelerates fuse degradation and may cause failure even under normal current conditions.

6. Aging and Material Fatigue

Over time, fuse materials degrade due to thermal cycling, oxidation, and mechanical stress. According to the Arrhenius aging model, elevated temperature exponentially increases material degradation rates, significantly reducing fuse lifespan—even when electrical stress remains within design limits.

Fuse failure is not limited to overcurrent conditions; environmental factors, installation quality, and aging all directly affect performance.

Dena Electric 6000 MCBs are designed with precise control of rated current, breaking capacity, and thermal behavior to ensure stable operation and prevent nuisance tripping or premature failure.

7. Moisture Ingress

Moisture or water penetration into building wiring can gradually deteriorate insulation and lead to short circuits. This increases current flow and circuit damage risk, causing the fuse to operate and disconnect power to maintain system safety.

| Cause of Fuse Failure | Explanation | Usage Examples |

|---|---|---|

| Overload / Short Circuit | Passing a current higher than the rated current causes the fuse element to melt | Motor Startup, Transformer Short Circuit |

| Mechanical Vibration | Formation of fine cracks in the fuse element due to vibrations or mechanical shocks. | Car Engine Compartment, Heavy Machinery |

| Extreme Temperatures | High temperatures accelerate oxidation; low temperatures cause material brittleness. | Outdoor Electrical Panels, HVAC Systems |

| Improper Installation | Loose connections increase contact resistance and cause localized heating. | On-site Mounted Fuse Holder |

| Aging and Fatigue | Material degradation over time due to continuous thermal cycling. | Industrial Control Panels with Long-Term Operation |

| Faulty building wiring and outlet connection | Improper installation, worn-out wire insulation, or faulty outlets can cause short circuits or current instability. | Old buildings, loose or burnt outlets, non-standard wiring in residential units |

| Moisture Ingress | Moisture causes insulation breakdown in wires and increases the risk of short circuits, causing the fuse to operate to prevent hazards. | Damp areas, parking lots, kitchens, and bathrooms |

Signs and Symptoms of Fuse Failure

Timely identification of fuse failure signs plays a crucial role in preventing equipment damage, unexpected shutdowns, and operational interruptions. These signs are generally divided into two categories: visual (physical) indicators and electrical indicators.

Visual Inspection Signs of Fuse Failure

Visual inspection remains one of the simplest and most effective initial methods for detecting fuse failures. The most common signs include:

Broken or melted fuse element, usually clearly visible in fuses with transparent bodies.

Discoloration, blackening, or burn marks on the fuse body or terminals.

Cracks, bulging, or deformation of the fuse housing.

These signs typically indicate overcurrent, abnormal temperature rise, or mechanical damage.

Electrical Indicators of Fuse Failure

In addition to visual signs, fuse failure can be accompanied by electrical disturbances, including:

Loss of power to equipment connected to the circuit.

Intermittent or unstable system operation due to opening and closing of contacts, especially caused by vibration.

Sudden system shutdown or partial loss of equipment functionality.

Early detection of fuse failure signs, whether through visual inspection or electrical indicators, helps address the problem before serious damage occurs and prevents costly interruptions in electrical system operation.

Effective Fuse Failure Troubleshooting

Proper troubleshooting of fuse failures helps identify the root cause of the problem and prevents repeated unwanted trips and equipment damage. Below is a step-by-step practical process for accurately diagnosing fuse failures.

1. Visual Inspection

First, check the fuse for physical damage, discoloration, cracks, or melted elements. Many failures can be detected at this stage.

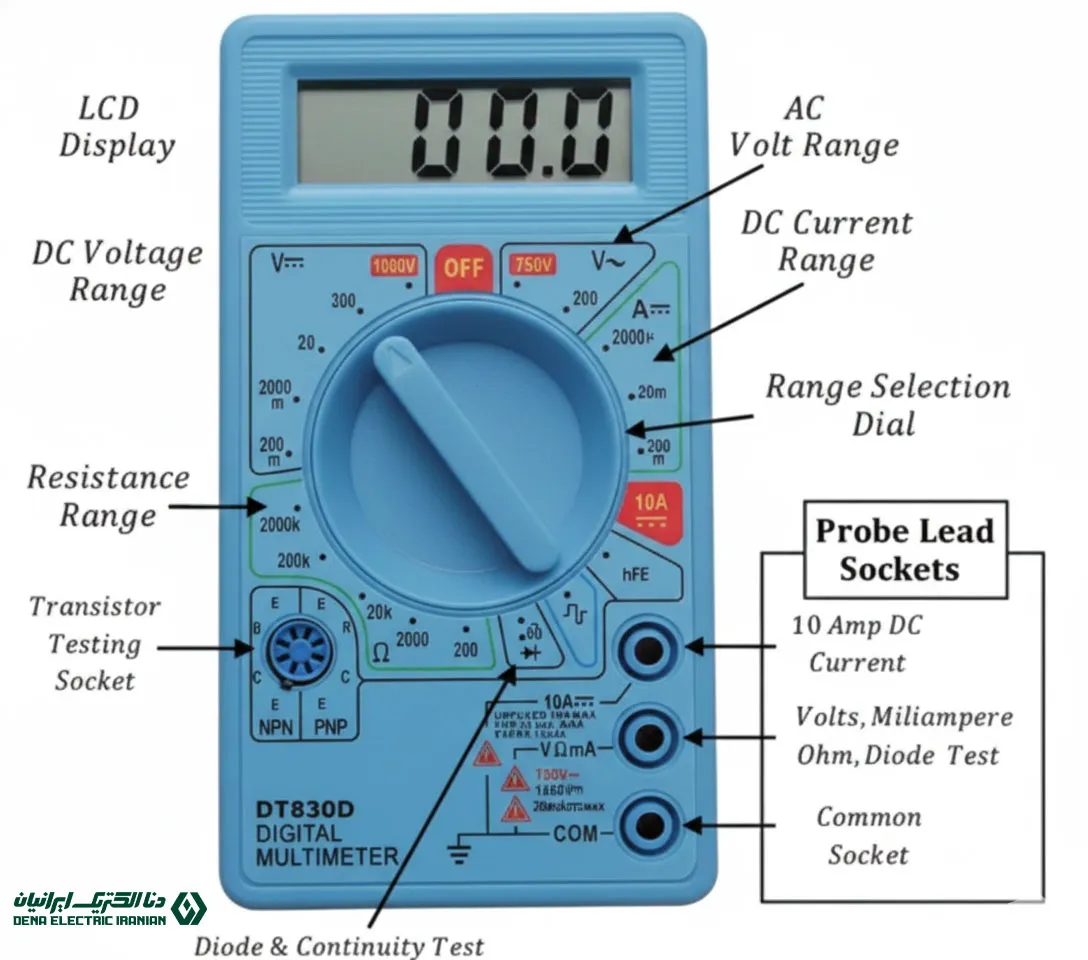

2. Continuity Test

Using a digital multimeter, check the circuit to determine whether the fuse is open or still intact.

3. Current Measurement

Measure the circuit load current and ensure it is within the fuse’s rated range. Excessive current may be the primary cause of failure.

4. Temperature Check

Use infrared thermography to identify hot spots. Localized temperature rises usually indicate high contact resistance or improper installation.

5. Root Cause Analysis

Determine whether the fuse failure occurred due to actual overcurrent, failure to follow temperature derating, or mechanical/installation issues.

Tools Needed for Accurate Fuse Troubleshooting

For professional and reliable troubleshooting, using the right tools is essential:

Digital multimeter for continuity and voltage measurements

Clamp ammeter to measure circuit current without disconnecting it

Infrared thermal camera to detect hot spots and thermal issues

Torque screwdriver to ensure proper tightening of terminals to the standard torque

Using a structured troubleshooting method along with appropriate tools ensures accurate diagnosis of fuse failures, preventing repeated failures, unnecessary downtime, and additional repair costs.

Preventing Fuse Failures: Best Design and Maintenance Practices

Preventing fuse failures is not limited to replacing them after they blow; proper design, careful selection, and regular maintenance can extend fuse life and prevent unwanted downtime. Below, we review the most important practical measures to prevent fuse failures.

Correct Fuse Selection and Derating

Choosing the right type and rating of fuse is the first and most important step in preventing premature failure. Attention should be given to:

Using the manufacturer’s temperature derating curves to match the fuse’s rated current to actual ambient conditions.

Correct calculation of I²t to ensure tolerance of inrush and fault currents without nuisance trips.

Selecting time-delay (Slow-Blow) fuses for circuits with inductive loads to accommodate startup currents.

Installation Guidelines for Increased Reliability

Proper installation directly impacts fuse performance and lifespan. To achieve maximum reliability, follow these steps:

Tighten terminal screws according to the manufacturer’s recommended torque.

Use fuse holders compatible with the appropriate contact rating.

Ensure secure and safe installation to reduce failures caused by vibration and mechanical shocks.

Inspection and Periodic Replacement Strategies

Implementing a preventive maintenance program plays a key role in reducing unexpected failures. This program may include:

Annual inspection of fuses for physical damage, discoloration, or corrosion.

Thermal imaging of holders to identify hot spots indicating contact degradation.

Periodic replacement of fuses based on the manufacturer’s recommended lifespan, even if no visible failure is observed.

By adhering to proper fuse selection, installation, and maintenance practices, repeated failures can be prevented, system safety can be enhanced, and repair and downtime costs can be minimized.

Industry Case Studies on Fuse Failures

Reviewing real-world case studies from various industries helps better understand the causes of fuse failures and select effective solutions. Below, we examine two practical examples from the automotive industry and industrial environments.

1. Fuse Failure in the Automotive Industry

In automotive applications, fuse failures are often related to factors such as high engine compartment temperatures, continuous vibrations, and incorrect fuse selection or installation.

For example, a 15-amp fuse used in a radiator fan system was repeatedly blowing.

Investigations showed that the engine compartment temperature could reach up to 125°C. Under such conditions, when the temperature exceeds 110°C, the fuse’s current-carrying capacity drops by about 80%, leading to frequent and annoying fuse blows.

Solution:

Selecting a fuse with a higher temperature rating along with vibration- and voltage-drop-resistant holders completely solved the problem.

2. Fuse Failure in an Industrial Control Panel

In a manufacturing plant, fuses related to a PLC control panel were intermittently failing.

Thermal imaging identified hot spots at the fuse holder contacts. The main cause was loose terminal screws, which increased contact resistance and consequently generated excessive heat.

Solution:

Tightening connections according to the manufacturer’s recommended torque eliminated hot spots, stopped repeated fuse failures, and improved system uptime and reliability.

These case studies demonstrate that fuse failures are not always due to overcurrent; environmental conditions, installation methods, and mechanical details play a crucial role in fuse performance. Attention to these factors is key to improving safety and stability in electrical systems.

Future Trends in Preventing Fuse Failures

With advancements in electrical technologies and increasing equipment sensitivity, the circuit protection industry is moving toward smarter and more reliable solutions. Below, we examine the most important future trends in reducing and preventing fuse failures.

Smart Fuses with Monitoring Capabilities

The new generation of smart fuses is equipped with current and temperature sensors, providing real-time information about the fuse’s health and the likelihood of imminent failure.

These IoT-based fuses enable predictive maintenance, allowing technical teams to take corrective actions before failures occur. This technology is particularly effective in critical systems such as data centers, sensitive industrial equipment, and electric vehicle batteries, reducing unexpected downtime.

Advanced Materials for Enhanced Fuse Reliability

Recent research focuses on developing nanocomposite fuse elements, materials that improve thermal conductivity, oxidation resistance, and mechanical fatigue strength.

Additionally, the use of advanced ceramic housings enhances fuse performance under high temperatures and harsh environmental conditions. These advancements make fuses more reliable for critical applications such as aerospace, heavy industry, and high-stress environments.

The combination of smart technologies and novel materials is transforming the future of circuit protection. These trends not only reduce sudden fuse failures but also significantly increase the safety, stability, and efficiency of electrical systems.

Accessible Links

Useful Links